Labels

- Design of Concrete Structures

- Midas Civil

- Staadpro

- General

- Bridge Engineering

- Earthquake Engineering

- Latest news

- Photos

- Specifications

- Indian Standard codes

- Interior Designing

- Discussions

- GIS

- Tower

- Drawings

- Property Noida

- Roads

- Staircase

- Batching

- Concrete

- Concrete Batching Plant

- Enviornment

- Excel

- Job

- Planning and management Softwares

- Plant

- Post Disaster Shelter

- Prompt

- Quality Control

- Railway

- Rehabilitation

- Skyscraper

- Soil

- Travel

- structure analysis

- water content

Monday, September 02, 2024

What is plinth beam ?

Plinth beam is a reinforced concrete beam constructed between the wall and its foundation.

- Plinth beam is provided to prevent the extension or propagation of cracks from the foundation into the wall above when the foundation suffers from settlement.

- Plinth beams distributes the load of the wall over the foundation evenly.

- Strength of plinth beam concrete shall not be smaller than 20MPa.

- A minimum depth of plinth beam is 20cm whereas its width should match the width of final course of the foundation.

- Recommended to provide minimum two bars with diameter of 12mm at the bottom of the beam. Similarly, two bars with minimum diameter of 10mm shall be provided at the top of the plinth beam. Reinforcement bars should be protected by 25mm concrete cover. As far as stirrups are concerned, stirrup diameter should be at least 6mm and a spacing of 15cm should be sufficient.

- Plinth supports column, structure.

- In framed structure, the plinth beam is the first beam to be built after the foundation.

- It stops the entry of moisture in the building, thus protecting wall from dampness.

- It assists to tie all the columns, reducing effective length of the column, thus avoiding the chance of buckling and keeping the beam and column connected.

Thursday, June 03, 2021

Important points for civil engineers

- Height of parapet wall should be = 1 m.

- Thickness of DPC is = 2.5 cm.

- Height of building = 3.15m.

- Height of window = 2.1 m.

- One bag of cement = 1.25 ft3

- Weight of one cement bag is = 50 kg.

- Minimum thickness of slab = 125 mm(5")

- No. of cement bags/m3 = 28.8 bags

- Lintel thickness = 15 mm

- Lintel is provided @ 2.4 m in case of brick wall.

- Minimum diameter of bars used in slab = 8 mm.

- Minimum diameter of bars used in column = 12mm.

- Minimum diameter of bars used in dowels =12mm

- Maximum diameter of bars in slab = ( 1/8) x thick of slab

- Maximum chair spacing = 1 meter

- Dimensional tolerance of cube = + 2 mm

- Maximum water absorption of first class brick = 15 % of its dry weight

- Initial setting time of cement = 30 min

- Final setting time of cement = 10 hours

- DPR = Detailed Project Report

- Unit weight:

- RCC = 25 kn/m3 = 25000 N/m3

- PCC = 24 kn/m3 = 24000 N/m3

- Steel = 7850 kg/m3

- Brick = 1600 kg/m3 = 16 kn/m3

- Soil = 1800 kg/m3 = 18 kn/m3

- 1 Gallon = 3.78 liters

- Minimum no. of bars

- For square columns = 4 bars

- For circular columns = 6 bars

- Standard sand in India is obtained from Ennore Tamil Nandu.

- 1 Yard = 3 feet

- Weight of steel = D2/162.2 kg/m or D2/533 kg/ft

- Size of concrete testing cube = 150 mm x 150 mm x 150mm

- Concrete cube is filled in 3 layers.

- Slump cone is filled in 4 layers.

- Cement should be used with in the 3 months of manufacturing.

- Minimum thickness of shear wall = 150 mm.

- Maximum thickness of shear wall = 400 mm.

- (UTM) Universal testing machine is used for compression test of concrete & tensile test of steel reinforcement.

Friday, May 21, 2021

What is structural engineering?

Structural engineering is a specialty of civil engineering that ensures the structures are safe, stable and don’t collapse under applied loads.

- They also helps to create beautiful structures, useful structures like bridges, rollercoasters, skyscrapers, hospitals and homes.

- They create drawings and specifications, perform calculations, review the work of other engineers, write reports and evaluations, and observe construction sites.

- They work as part of a team along with architects, builders and other engineers.

- They design buildings so they’re strong enough to support the loads on them (like people and equipment) and stable against elements like wind.

- They study how to stop buildings from falling down during earthquakes, hurricanes, and other natural disasters.

- They do analysis by determining forces in each element in a structure.

Structures are subject to vertical, or "Gravity" Loads and horizontal, or "Lateral" Loads. Gravity loads include "dead", or permanent, load, which is the weight of the structure, including its walls, floors, finishes, and mechanical systems, and "live", or temporary load, which is the weight of a structure's contents and occupants, including the weight of snow. Lateral loads include those generated by the wind, earthquakes, or explosions. Structural elements must be designed so that, as a system, the structure can resist all loads that will act upon it.

So main responsibility is -

- collaboration with structural engineers, architects, owners and construction managers, architects decide on the effectiveness, feasibility and cost-effectiveness of concepts.

- Assessing the reaction of structures to pressures and stress.

- Finalizing material requirement

- Assessing budget

- Construction management, should be completed on time.

Thursday, March 04, 2021

What is the difference between a steel lintel and an RCC lintel?

A lintel is a horizontal load bearing member in construction. Lintels support wall or wall cladding above window and door openings.

Steel Lintel

Steel lintels are generally made from pre-galvanised steel which is cut and either roll-formed or pressed into the required shape. Steel has the advantage over concrete in that the lintels are usually lighter and are easier to handle on site.

These are used when the superimposed loads are heavy and openings are large. These consist of channel sections or rolled steel joists. We can use one single section or in combinations depending up on the requirement. When used singly, the steel joist is either embedded in concrete or cladded with stone facing to keep the width same as width of wall. When more than one units are placed side by side, they are kept in position by tube separators.

Reinforced Cement Concrete Lintel

At present, the lintel made of reinforced concrete are widely used to span the openings for doors, windows, etc. in a structure because of their strength, rigidity, fire resistance, economy and ease in construction. These are suitable for all the loads and for any span. The width is equal to width of wall and depth depends on length of span and magnitude of loading. RCC lintels can have a finish matching other components and details of the façade, unifying the entire design. Rebar's in RCC lintels can be epoxy coated to prevent corrosion.

Wednesday, March 03, 2021

What is the difference between trapezoidal load and hydrostatic load?

Slab pressure loads (Kn/m2) are transferred to supporting beams as line load (kn/m) which can be triangular, trapezoidal, or partially distributed. Slab having two unequal sides distribute trapezoidal load on longer side beam.

Hydrostatic load: The pressure exerted by a fluid at equilibrium at a given point within the fluid, due to the force of gravity. Hydrostatic pressure increases in proportion to depth measured from the surface because of the increasing weight of fluid exerting downward force from above. Hydrostatic load can be trapezoidal but trapezoidal load cannot be hydrostatic. Because hydrostatic load occur due to water.

Friday, February 19, 2021

Can I erect a 9-inch wall over a 4-inch reinforced concrete slab?

I think you can design slab for taking load of 9" brick wall. First check that slab can take one way acting shear generated due to load. considering 9" wall weigh 0.54 t/sqm /m height and 3.0 m height of wall will have load of 0.54*3=1.62 t/m length. As load is transferred through two edges ,each edge will have shear force of 0.81 t/m. hence depending upon thickness of slab and % of steel the shear stress will be tv if this is less than tc then load transfer is o.k. Considering the line load on the slab identify effective width for calculation of B.M. per unit length and then design the slab.

However as in any other case since slab is supporting wall, as rightly pointed deflection will have to be checked so that additional deflection is not greater than span/350 or 20 mm whichever is lower.

Wednesday, February 10, 2021

Why are newly constructed or ongoing construction buildings covered in green cloths?

The green cover provided around the building under construction prevents:

- People who are passing by become cautious of a construction site around, can take care of safety measures required.

- any dust or debris spreading out to the surrounding.

- The accidental fall of debris / pieces to fall on the people who may be standing underneath or might be passing from the nearby walk ways.

- from direct sunlight . It also maintain ventilation

Friday, January 08, 2021

Why Earthquake Effects are to be reduced?

First question arise why there is need of reducing earthquake effect on buildings.

Due to Seismic Design structural buildings do not collapse under strong earthquake shaking. But, it may damage to non- structural elements like glass facades.

Seismic designed building are more costlier, but this cost is justified through improved seismic performance.

Sunday, July 05, 2020

Ground Connection of Columns by a Strap Beam

Wednesday, August 07, 2019

Thursday, March 22, 2018

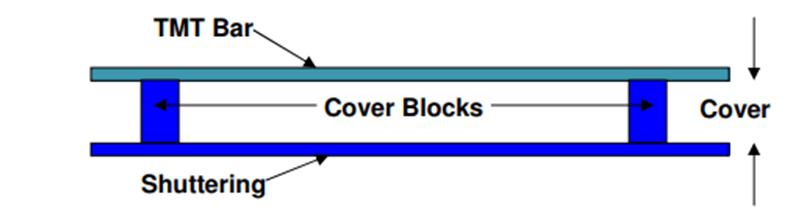

What are Concrete Cover Blocks?

Cover blocks are used to maintain a specified distance between the TMT rebar and the shuttering.

or

A cover block is essentially a spacer that is used to lift the rebar matrix off the ground so that concrete may flow underneath the rebar.

Why we must use cover blocks?

- When doing RCC work it is important to embed the steel in the concrete (also known as cover) so that the rebar doesn’t corrode and to provide fire protection to the rebar.

- If we don’t provide the recommended cover the rebar will corrode with time and will ultimately result in premature failure of the structure.

- Thus using cover blocks enhances the life of the structure significantly without adding much to the cost.

Tuesday, March 06, 2018

Monday, March 05, 2018

Monday, February 26, 2018

Advantage and Disadvantage of Raft Foundation

- Raft or mat foundation is economic due to combination of foundation and floor slab.

- Better water- proofing treatment ease of reinforcement fabrication and laying of concrete.

- Mat foundation is one of the most dependable solution to uneven and difficult land areas. Sometimes the soil has a low bearing capacity while other times, making individual footing is not feasible. A mat foundation is the solution to these problems.

The excavation required for the mat foundation is way less than what is required by other foundation. This saves resources, labor as well as money.- In case of soil having low bearing pressure, Ultimate Bearing capacity increases with increase width of the foundation. Settlement decreases with increase depth. The amount of differential settlement between various parts of a structure is much lower than that if the same structure was supported on individual footing. Hence, maximum total settlement which can be allowed for a particular structure is more than what is permitted when the structure is resting on individual footing.

- Mat foundation is perfect for soil that is subjected to subsidence. For e.g. clay is a kind of soil that keeps on contracting and expanding as the temperature changes, this is why, building a structure directly on the soil can make it dangerous.

- It reduces differential settlement.

- The soil has a low bearing capacity so the weight of the building needs to be spread out over a large area to create a stable foundation.

- If the walls of the building are so close that it would cause the individual footings to overlap, then raft foundations should be used.

Saturday, February 24, 2018

Low Density and Thermal Efficient Concrete for Terrace Overlay

- Better thermal insulating capability

- Easier to place and saves time (surface is ready to use within 24hrs)

- Reduces dead load on existing structures

- Exceptionally low densities are available up to 800 kg/cum.

Thursday, February 22, 2018

How to calculate weight of mild steel bar?

| Weight | = | Volume x density | |

| Since its cylindical shape | |||

| Volume of bar | = | pi()*h*(d²)/4 | mm³ |

| where | h is height of cylinder bar | ||

| d is diameter in mm | |||

| Weight density of steel | = | 7850 | kg/m³ |

| Here we considering for 1m length, so h = 1m | |||

| Volume of bar | = | pi()*h*(d²)*(10⁻⁶)/4 | m³ |

| = | pi()/4*h*(d²)*(10⁻⁶) | ||

| Here we have coverted dia from mm to m | |||

| Volume of bar | = | (7.85*(10⁻⁷))*(d²) | m³ |

| Weight of bar | = | Weight density x Volume | |

| or unit weight of steel | = | 7850*(7.85*(10⁻⁷))*(d²) | |

| = | 0.00616225 | *d² | |

| or can be written as | = | d²/ | 162 |

| where d is diameter of bar in mm | |||

| Example | |||

| 25mm bar weight per meter = | 25*25/162 | ||

| = | 3.858024691 | kg | |

| Weight of steel | = | (d²/162)*length | |

Wednesday, February 21, 2018

Corrosion Monitoring of Reinforced Concrete Structures

- Exposure condition (Access to moisture, oxygen, exposed to de-icing salts, other chemicals, carbon dioxide);

- Geometry of the structures and components;

- Access to structural and non-structural components;

- Dimension and scale of the area under investigation;

- Importance of the element, etc.

Chain dragging is widely used to detect delamination in concrete bridge decks. The concept behind this very simple method is the unique hollow sound that is made by dragging chain across the delaminated surface. The test is used to identify potentially delaminated areas on the deck slab.

The practice is difficult when vehicles are moving over the deck, and distinguishing the hollow sound becomes difficult.

The main disadvantage of the chain dragging method is that they can only provide results if the defect and deterioration are in well advanced stages. Early diagnosis of damage mechanism is not possible using this technique. Application of the method is somewhat difficult during heavy traffic.